Application of Static Grounding Monitoring System

Legislation

concerning static electricity in hazardous area process industries

The ignition risk posed

by static electricity is addressed in European and North American legislation.

In the US, the Code of Federal Regulations that addresses hazardous location

activities, 29 CFR Part 1910 "Occupational Safety and Health

Standards", states that all ignition sources potentially present in

flammable atmospheres, including static electricity, shall be mitigated or

controlled.

In Europe, Annex II of

the ATEX Directive 2014/34/EU states the following:

Section: 1.3.2 Hazards

arising from static electricity: Electrostatic charges capable of resulting in

dangerous discharges must be prevented by means of appropriate measures so

"electrostatic discharges" are a known potential ignition source and

must be considered as part of the explosion risk assessment.

Safety

directives and function safety

Safety

directives

Anti-spill and

electrostatic grounding systems loaded on tank trucks shall comply with the ATEX

directives and standards. The system meets the general requirements of EN60079-0,

EN60079-1 and EN60079-11 for intrinsically safe circuit boards and electric

equipment.

ATEX specifies minimum

safety requirements for use in explosive atmospheres.

Its purpose is to

ensure that equipment such as oil spill sensors and control monitors do not

pose an ignition risk in an explosive atmosphere. ATEX does not assess the

safety function of the system, that is, its ability to detect liquid product

and stop the flow of product.

Function

Safety

Function safety

standards focus on the ability of a system to properly perform its safety

function, that is, to detect hazards and implement automatic protections to

ensure that in the event of a fault, the system fails in a predictable and safe

manner. Accredited functional safety bodies should carry out functional safety

certification to provide an unbiased assessment of the design and performance

of safety systems.

Operator

training

Every year in the

world, many oil depots and gas stations explode and catch fire due to improper

operation of operators. Therefore, it is essential to strengthen operator

training in flammable and explosive areas and should not be ignored. Operators

working in EX/HAZLOC areas should be trained in the basics of electrostatics!

They should be trained

on the intended function and proper use of grounding equipment and the use of

grounding equipment in accordance with company standard operating procedures.

For example, when loading and unloading oil into metal barrels, many operators

do not directly ground the metal barrels, and directly start the process of

paying and unloading oil. In this process, a large amount of static electricity

will be generated and cause accidents.

Operators should be

trained to avoid the following situations:

For example, if the grounding system and process interlocks have their ground connections removed from the process, thereby initiating an emergency shutdown process (e.g. switching down a pump), there may still be movement of material after the machine is stopped, thereby assuming the risk of continued electrostatic charge generation. If operators notice equipment has been changed or damaged (e.g. frayed cable connections), they should be encouraged to report the matter to the relevant personnel location (line manager, local maintenance staff) until someone who is able to use the equipment believes the equipment is safe and appropriate to use. Failure to provide training risks improper use of grounded equipment and/or failure to follow company standard procedures regarding static control.

Before the installation

of our equipment, we will provide professional guidance to the on-site

operators, and return visits regularly to supervise their normal operation.

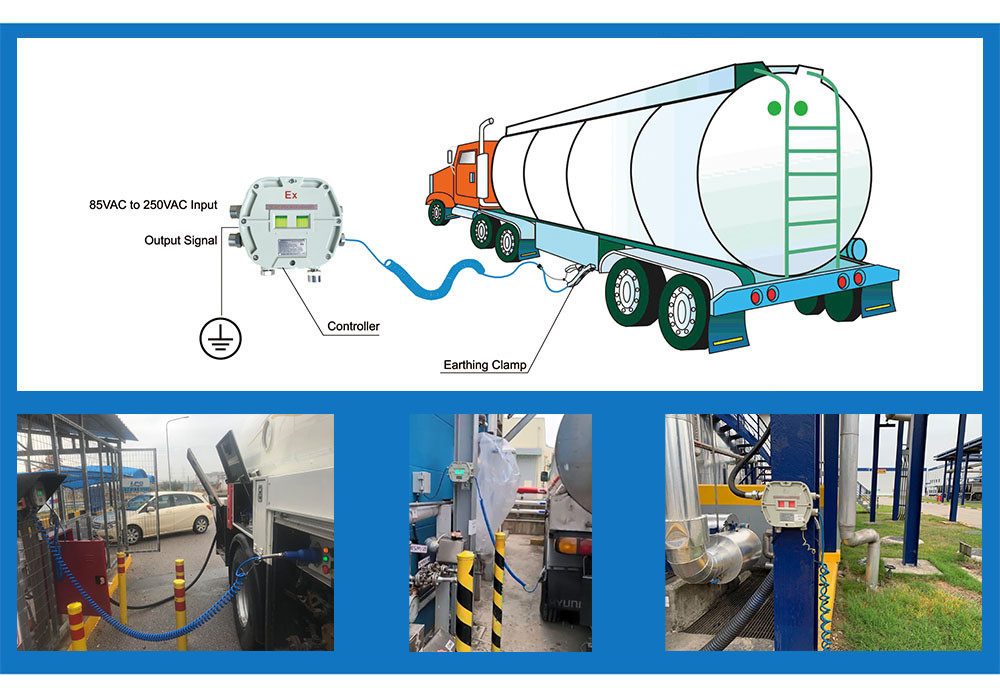

Application

1. Road

tanker truck flammable

2. Filling,

mixing and blending of flammable/combustible materials in drums, portable

containers, mobile tanks and railcars.

3. Railway

loading and unloading, etc.