Maintenance Manual of Retractable Grounding Reel

1.0

Introduction

Retractable

Grounding Reel (RGR)is designed to provide the lowest impedance connection

between the shell of a floating roof tank and its roof by creating the shortest

possible path between the two. This connection is obtained by keeping constant

tension on the braided cable.

The

RGR can be installed during erection, maintenance shut downs or during regular

operation of a tank. It needs minimal maintenance and is easy to install on

both new and existing tanks in petrochemical facilities

NOTE:

All site safety policies and procedures must be followed.

Site

permission must be obtained prior to any maintenance of equipment. While the

LEC recommends the activities outlined in this document, each site is unique

and must follow its own requirements, procedures, and protocols.

2.0 Maintenance Frequency

RGRs

are often installed in corrosive environment. The more corrosive the

environment, the more frequently inspection and maintenance must be performed.

At a minimum, the following should be performed in an annual basis.

1.

Remove build-up from RGR cable and reel.

2.

Visually inspect the RGR cable for dirt, corrosion or tear; if there is a tear

in the cable, replace immediately.

3.

Ensure that all mounting base and bolts are mechanically tight. Tighten any

loose hardware immediately.

Note:

Never remove the reel from the mount if there is tension in the springs as the

handles will rotate in an uncontrolled manner.

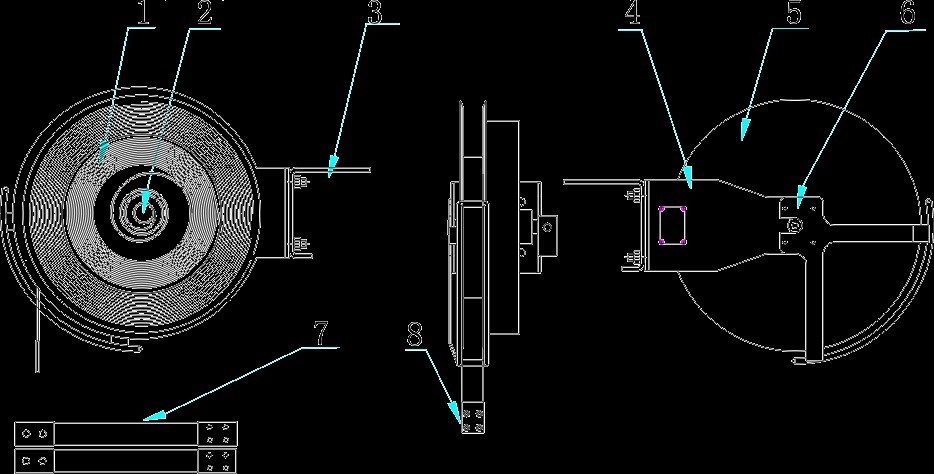

1 Spring 2 Axle 3 Horizontal Bracket 4 Mounting Base 5 Reel 6 Wire Guide 7 Ground Ends

8 Braided Cable

3.0

Equipment and Materials

Access

to the RGR is very simple and can be inspected and maintained using common hand

tools, as listed below. If permitted, photographs should be taken to document

the condition and method of connection between each RGR reel and the tank top,

as well as the connection of each ground strap to the foam dam or tank top.

Required

inspection items

Digital

camera

Digital

multimeter (DMM)

adjustable

wrench x 2

Wire

wheel or brush

Sanchem

Inc. NO-OX-ID “A-Special” or other electrically conductive lubricant

Lectra

Shield or other electrically conductive corrosion inhibitor

4.0

Maintenance Process

4.1

Tank top inspection

4.1.1

Visually inspect the interface between the RGR bracket and the tank wall.

During installation, paint and rust must be removed from all contact surfaces

to ensure good contact. Contact surfaces should be sealed with a conductive

corrosion inhibitor to provide a reliable electrical connection between the RGR

bracket and the tank wall.

4.1.1.1

Use

a digital multimeter (DMM) to measure the resistance between the RGR cable and

the tank wall. Verify that there is no measurable resistance or measurement is

less than 0.03 ohms.

4.1.2

Keep the reel clean.

4.1.3

Verify that the nuts and bolts securing the RGR are securely tightened.

4.1.4

Visually inspect the main cable for dirt, buildup,

corrosion or tears.

If the main cable is

torn or frayed, consult the factory for a replacement cable.

4.2

Ground straps

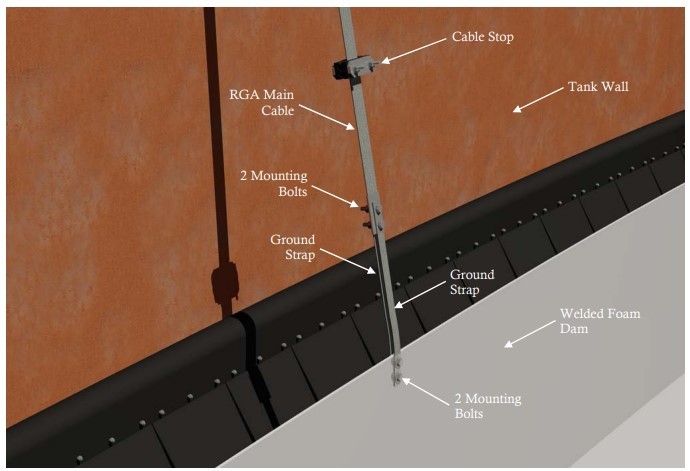

4.2.1

Confirm the connection of the two ground straps to the RGR main cable

4.2.2

Visually inspect the ground straps for dirt, buildup, corrosion or tears.

If

the ground straps is torn or frayed, consult the factory for a replacement

cable.

4.2.3

Visually inspect the interface between the ground strap and foam

Dam/floating

roof connection point. During installation, paint and rust must be removed

between all interface surfaces to ensure bare metal is exposed metal contact.

4.2.3.1

Use a digital multimeter (DMM) to measure the resistance between the RGR cable

and the floating roof . Verify that there is no measurable resistance or

measurement is less than 0.03 ohms.

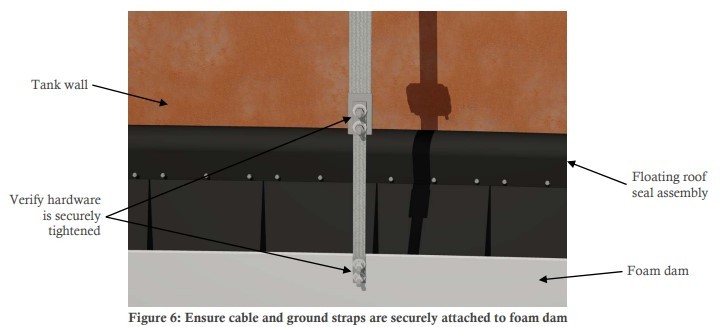

4.2.4 As shown below in Figure 6, verify that all nuts and bolts connecting the RGR main cable to ground straps and ground straps to foam dam or floating roof connection point are securely tightened.

5.0

Technical Support

For

technical support please contact:

Qingdao

Alptec Safety Equipment Co., Ltd.

No.13

Hancheng Road, Qingdao Free Trade Zone, Shandong Province, 266555. P. R. China

Cell:+86

18766256959 | Tel:+86 (0) 532 8689 4009

Email:grace@alptec.com

| Skype: grace@anysafe.net | www.staticgrounding.cn